PROJECT DETAILS

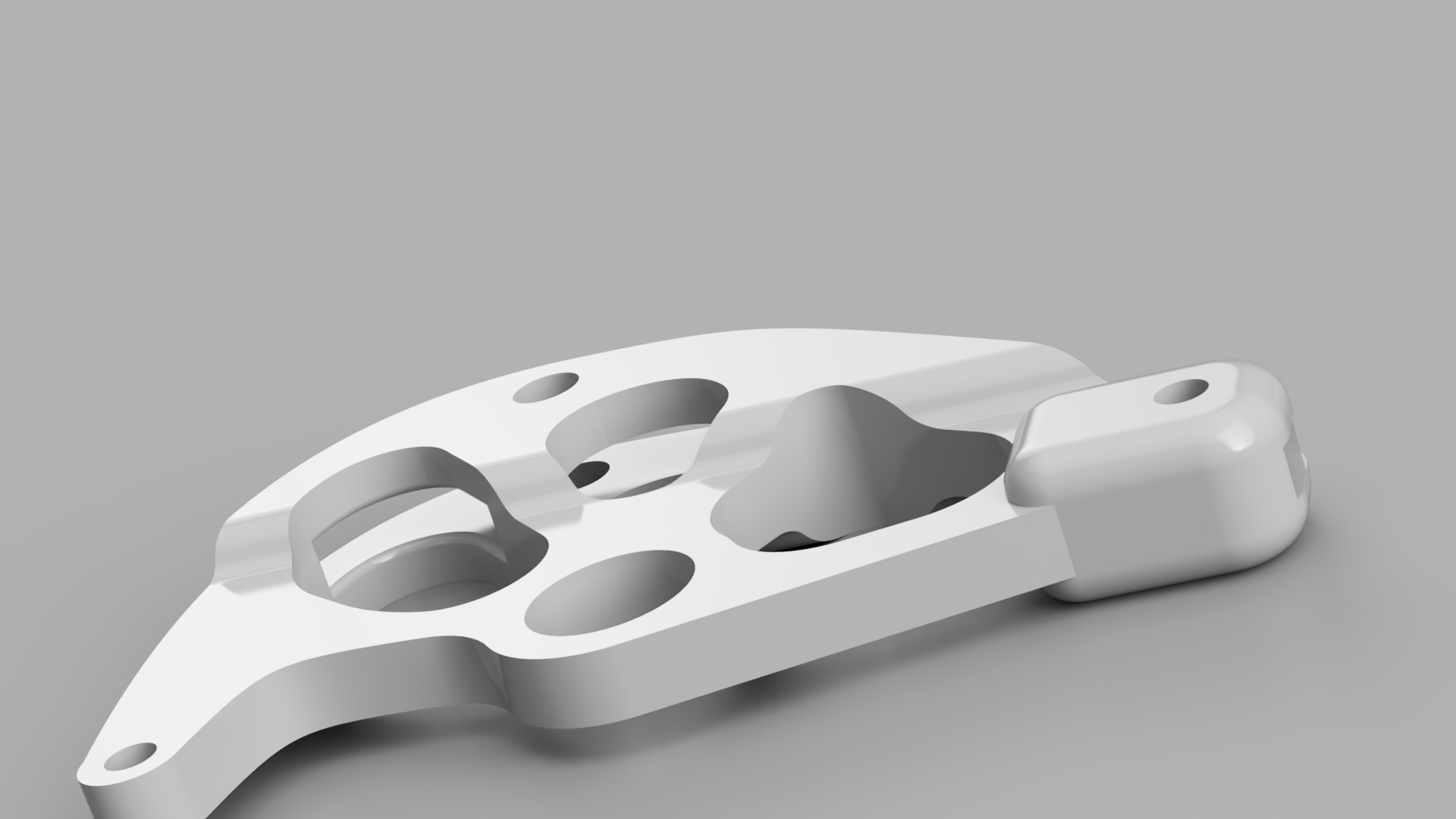

Bell Bracket - Topology Optimization for Additive Manufacturing

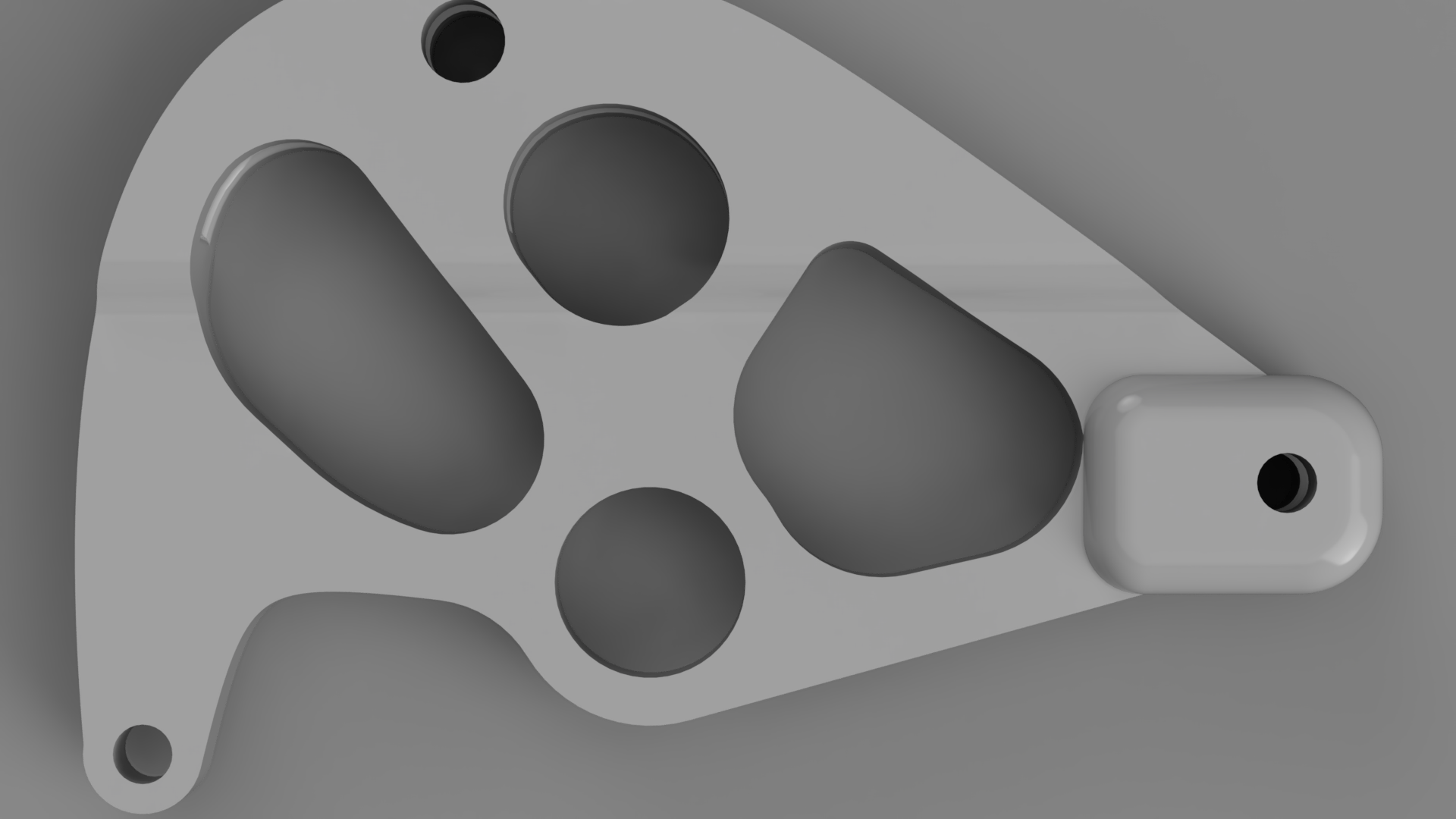

This project involved the design and optimization of a bell bracket using topology optimization in Fusion 360. The goal was to create a lightweight, functional structure that fits within predefined dimensions while ensuring it could withstand a 5kN load using LUVOCOM® 3F PET CF 9780 BK material for additive manufacturing.

PROCESS

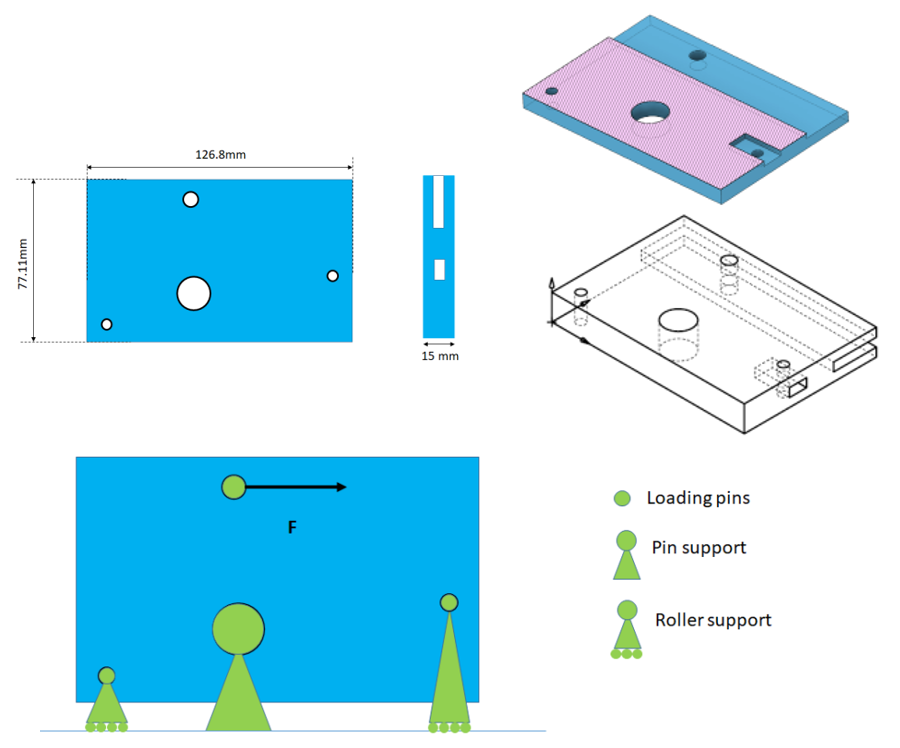

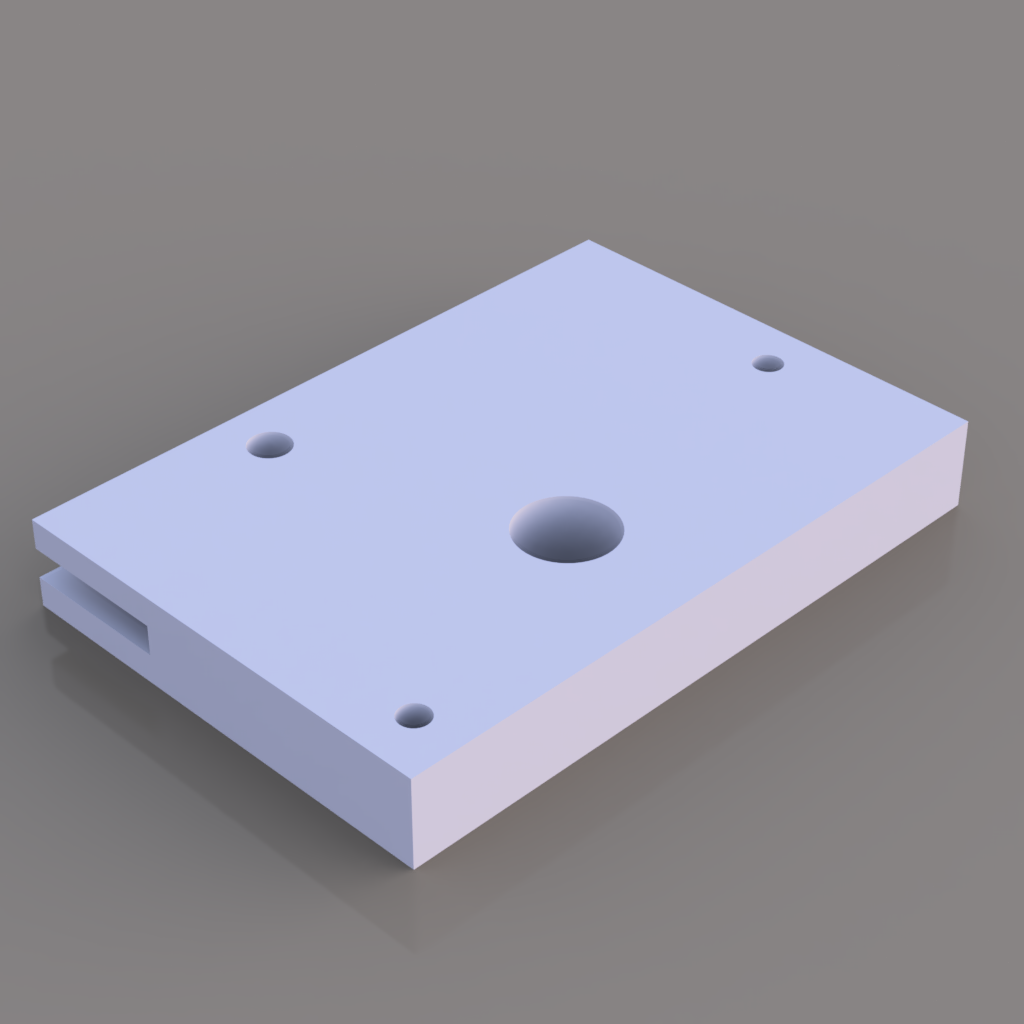

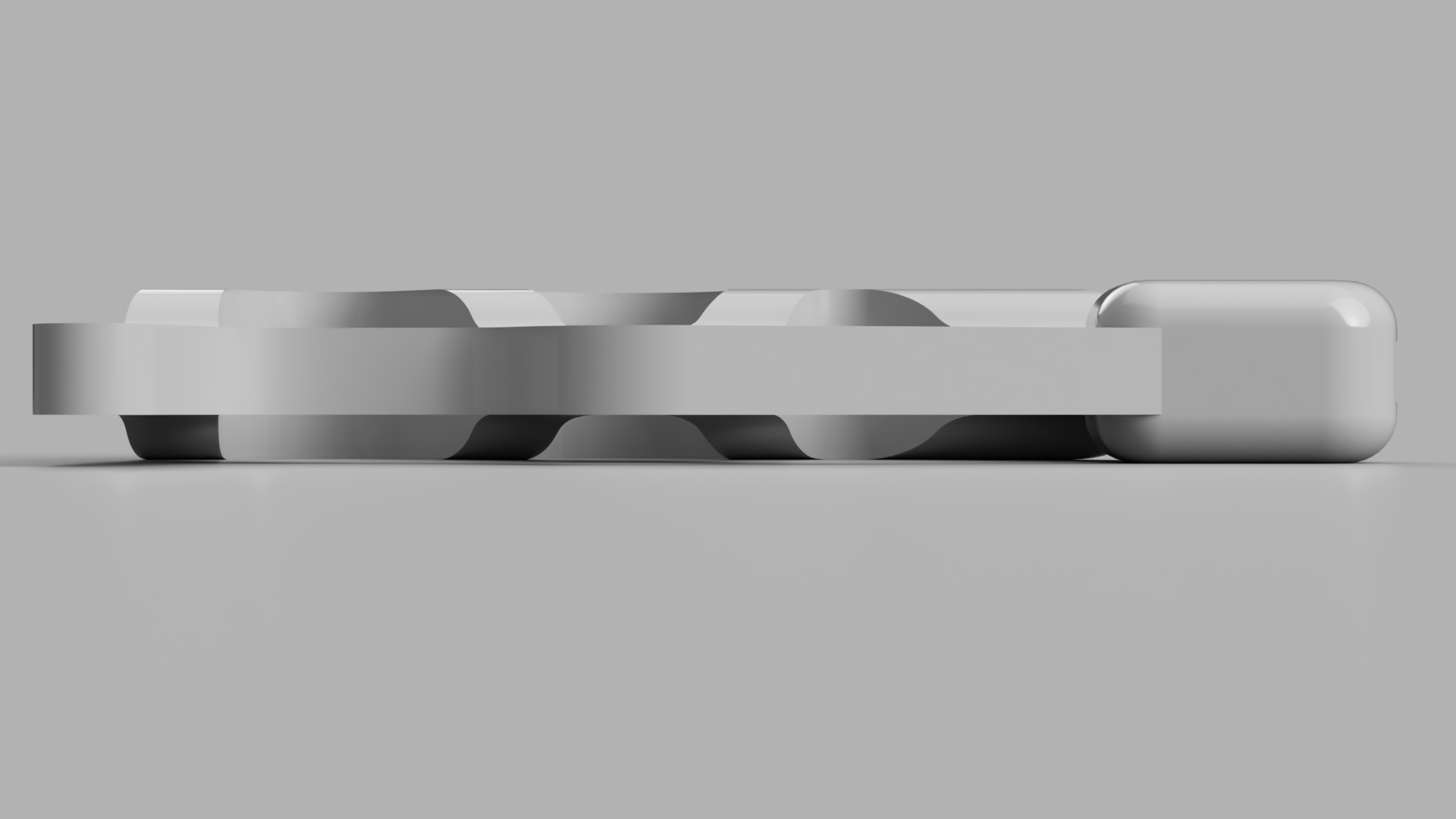

The design process began by defining the allowable design space for the bell bracket, set at 77.1mm x 112.3mm x 15mm. Boundary conditions were established with a 5kN load applied along the positive X direction, fixed roller supports, and pin constraints, which guided the topology optimization in Fusion 360.

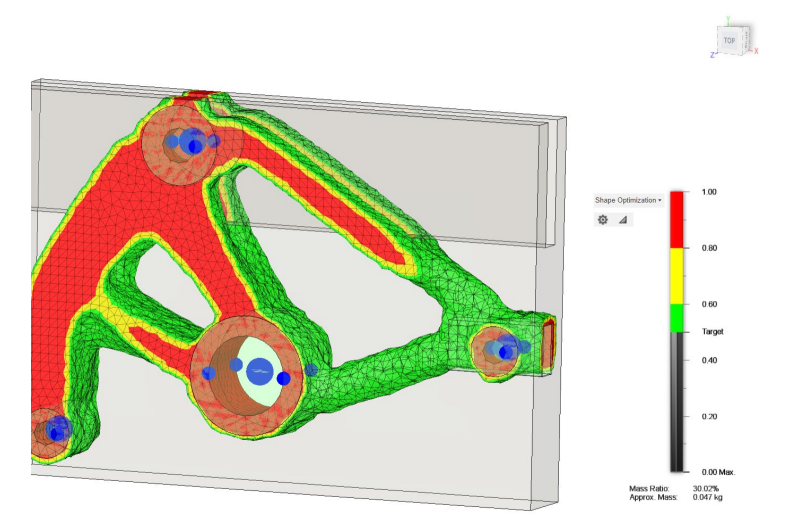

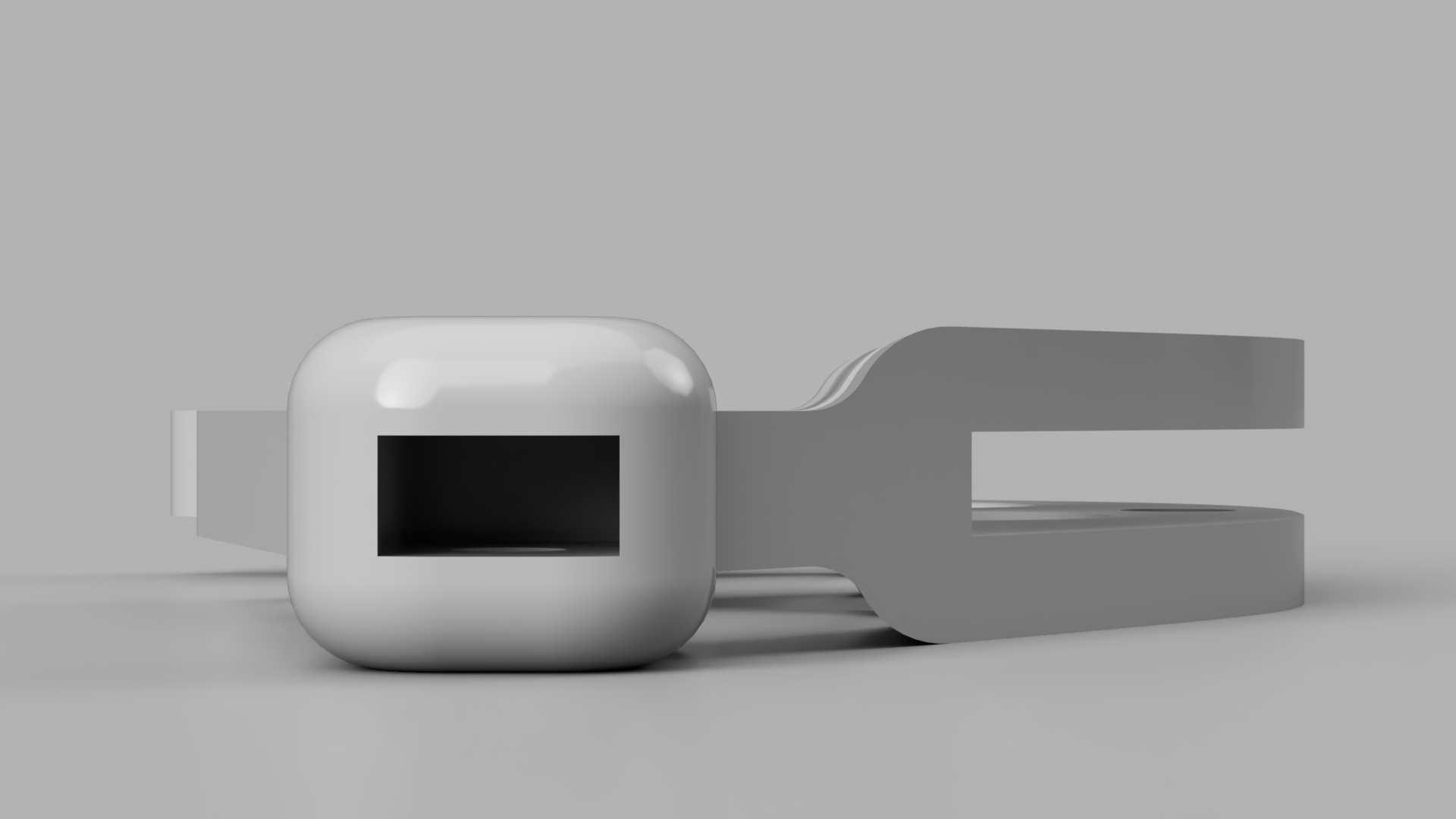

Once the design space and boundary conditions were set, Fusion 360 was used to perform topology optimization. The goal was to maximize stiffness within the space while keeping the weight of the bell bracket as low as possible. The optimization process generated multiple design iterations for evaluation.

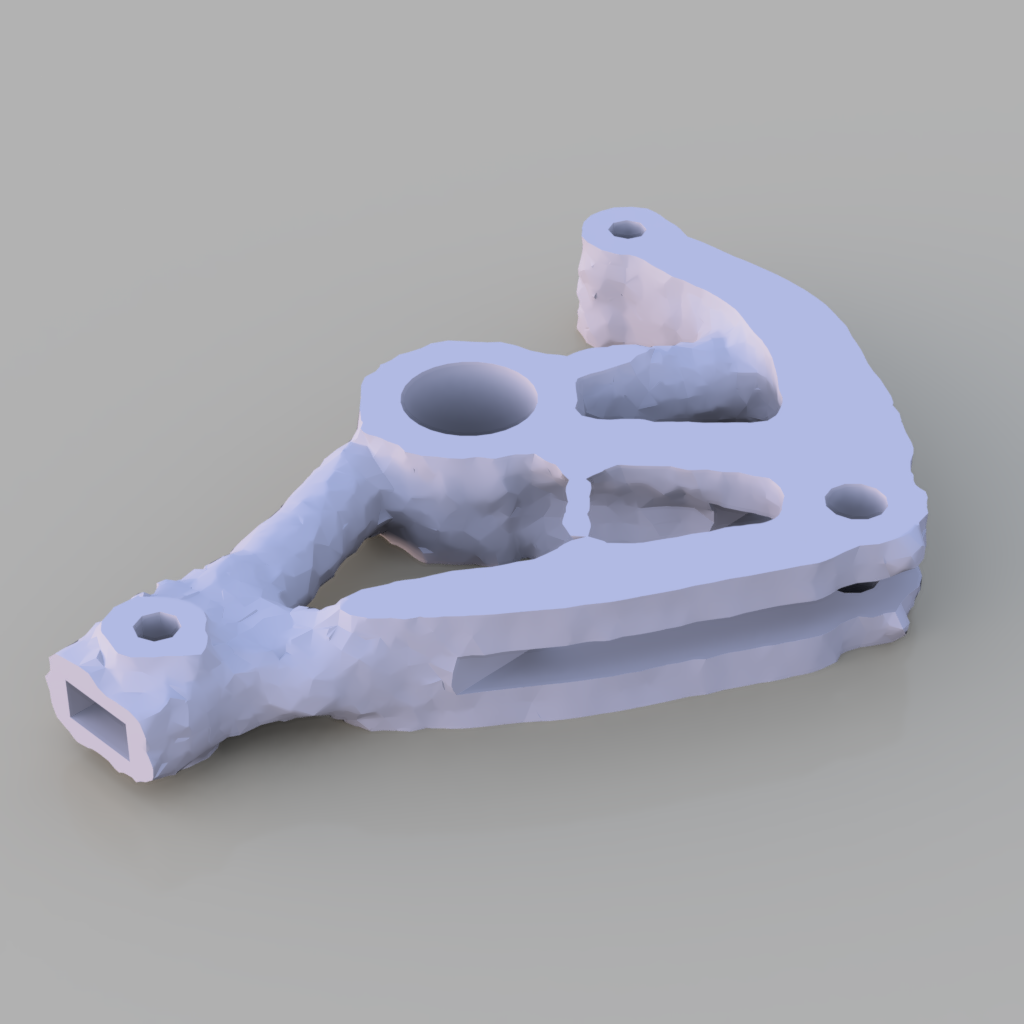

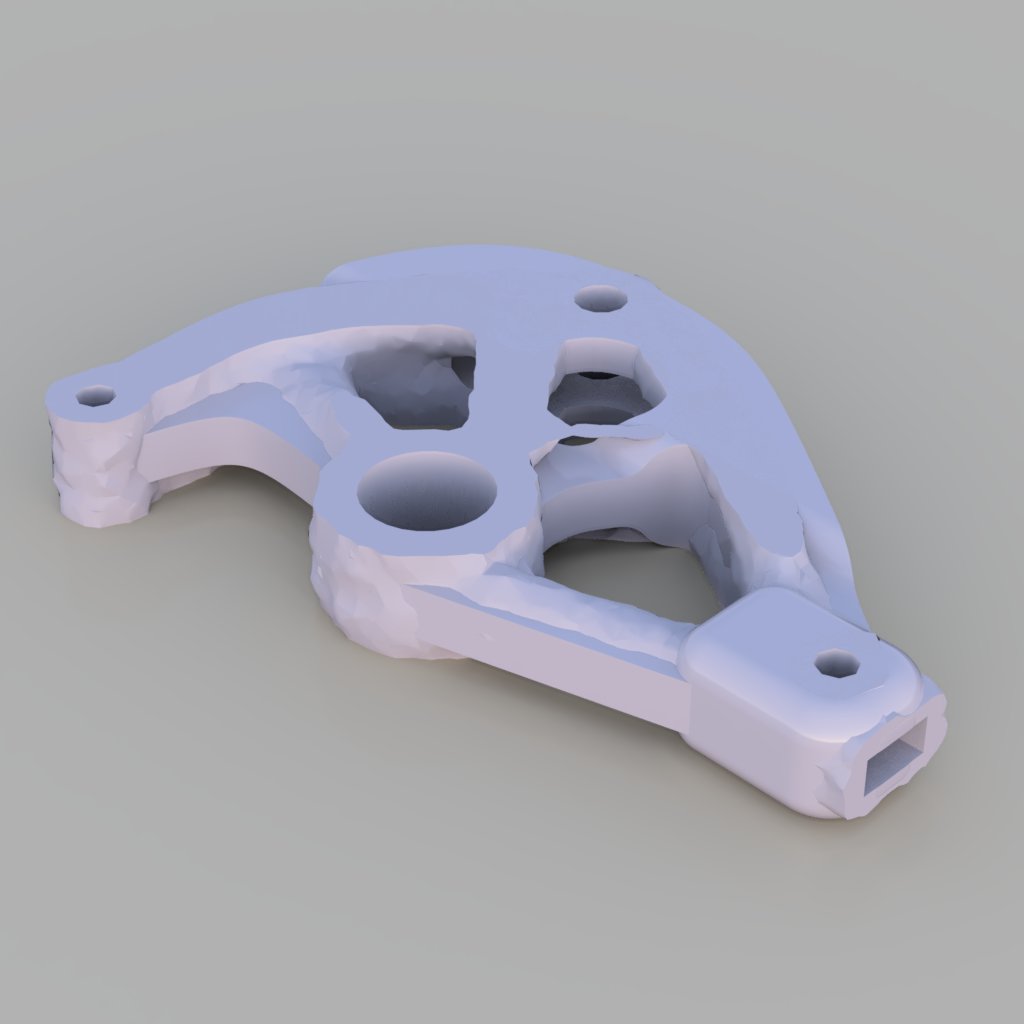

After running the topology optimization, the generated design was reviewed and further refined. This step involved adjusting the geometry to ensure it met all functional and manufacturing requirements, while also checking the safety factor for load-bearing capacity.

Here is some views of the final design, showing its structure and how it meets the design and load-bearing requirements.

Built with Reflex